With Isola Naida hauled out, our attention has shifted from sailing days to project planning and steady progress ashore. This past week, a few long-awaited deliveries arrived—giving us the parts we need to advance our settee project, start planning the head refit, and continue preparing for the dinghy repairs that have been on our list since early September.

Starboard Settee Storage Project

The final round of components for the starboard settee storage project arrived this week: heat shrink tubing, electrical connectors, tinned wire, magnetic reed switches, and LED strip lighting. With everything now on hand, we’ll begin wiring and installing the lighting system that will run beneath the settees in the main cabin, starting with the starboard side.

We’re planning to integrate the lights into the existing 12V circuit. Each hatch will have a magnetic reed switch which will automatically turn the LED strip on when the hatch is opened. This will make it easier to see the items in the under settee storage spaces, especially in low-light conditions.

Head Refit

Isola Naida currently has an AirHead composting toilet onboard. While these systems have their advantages—especially for minimizing through-hulls and simplifying waste management—the near-daily maintenance and composting requirements have proven to be more work than we’d like in the long term. We decided early on that we’d rather invest in refitting the head to a more traditional marine setup with a proper holding tank, electric macerating toilet, and the plumbing required for pump-out and overboard discharge (where permitted).

Originally, Isola Naida was built with a direct discharge head, so we’re fortunate that the through-hulls and seacocks are already in place. Our plan now is to install a new holding tank, deck pump-out fitting, and a topside vent. We’ll also integrate the new head into our freshwater system, which consists of three large tanks—more than enough capacity for flushing water for two people.

Right now, we’re leaning toward the 12V Dometic MasterFlush MF 7120, if we can find one available, which offers the 360° ORBIT and a built-in macerator. It’s compact, efficient, and reasonably priced compared to similar systems. Once the parts are sourced, we’ll lay out the plumbing plan and start the installation this winter while the boat’s on the hard.

Tender Repairs

Our RHIB has served us well, but two of the three sponsons have had slow leaks ever since we took ownership of the boat. A close inspection last week revealed several pinhole punctures and a razor thin slice in the sponsons. The leaks are slow enough that

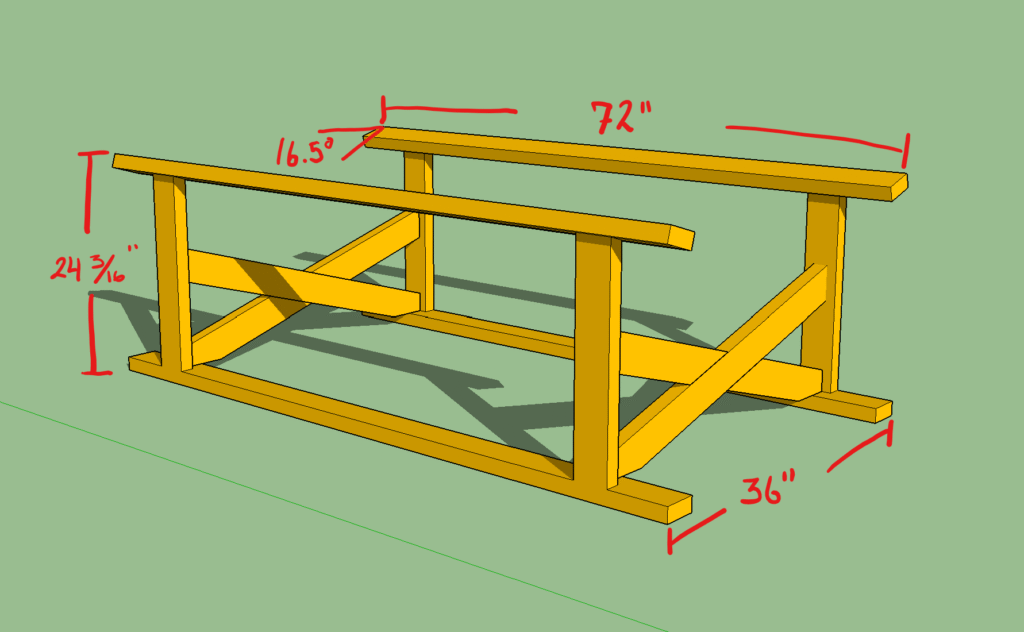

Before we begin patching, we want to build a cradle to support the dinghy at a comfortable working height, and to keep it from sitting on the ground over the winter. This will make it easier to work on the hull and ensure it doesn’t develop new stress points while stored.

Constructing the cradle required:

- Six 8′ lengths of 2×4 of lumber

- Two 6′ lengths of 3/4″ pipe insulation

- Twenty-four 3″ deck screws

- Twelve 1 1/2″ deck screws

- Twelve fender washers

- Staple gun and staples

After cutting the lumber and screwing everything together, we used the two 6′ lengths of pipe insulation to pad the angled beams that will make contact with the hull of the boat. Opening the seam of the insulation we wrapped it over the with of the 2×4 and secured it with fender washers and 1 1/2″ screws, spacing them evenly on each side. Once it was secured in place, we used a staple gun to help keep the edges of the insulation from curling back under itself.

Once secured in its cradle, we gave the tender a thorough clean using Spray Nine Marine cleaner. Next, we’ll be ordering a patching kit to make the repairs. Check back for a Boat Work post all about the tender.

After the patches are made and the oarlock is reattached, we’ll sew a new sponson cover using the old one as a pattern. This time, we’re planning to add flexible plastic inserts inside the fabric panels to provide extra protection against abrasion—especially when docking or hoisting the tender alongside Isola Naida. With a bit of luck, this refit should keep the dinghy seaworthy for many more seasons.

Looking Ahead

With these projects underway, our focus for the next few weeks will be on completing the settee lighting installation and ordering the components for both the head refit and tender repairs. The to-do list is long, but progress, no matter how incremental, always feels satisfying when it’s moving us closer to getting Isola Naida ready for next season.

Until next time.