When we took stewardship of Isola Naida, we also adopted her tender, a Caribe Nautica MVPL-10 Rigid Hull Inflatable Boat (RHIB). Caribe has long been known for their quality inflatable boats and we were excited to have a RHIB as a tender – their stability and carrying capacity is unmatched. Now that we have the boat out of the water for the season we’re able to address the leaks and prepare the tender for next season.

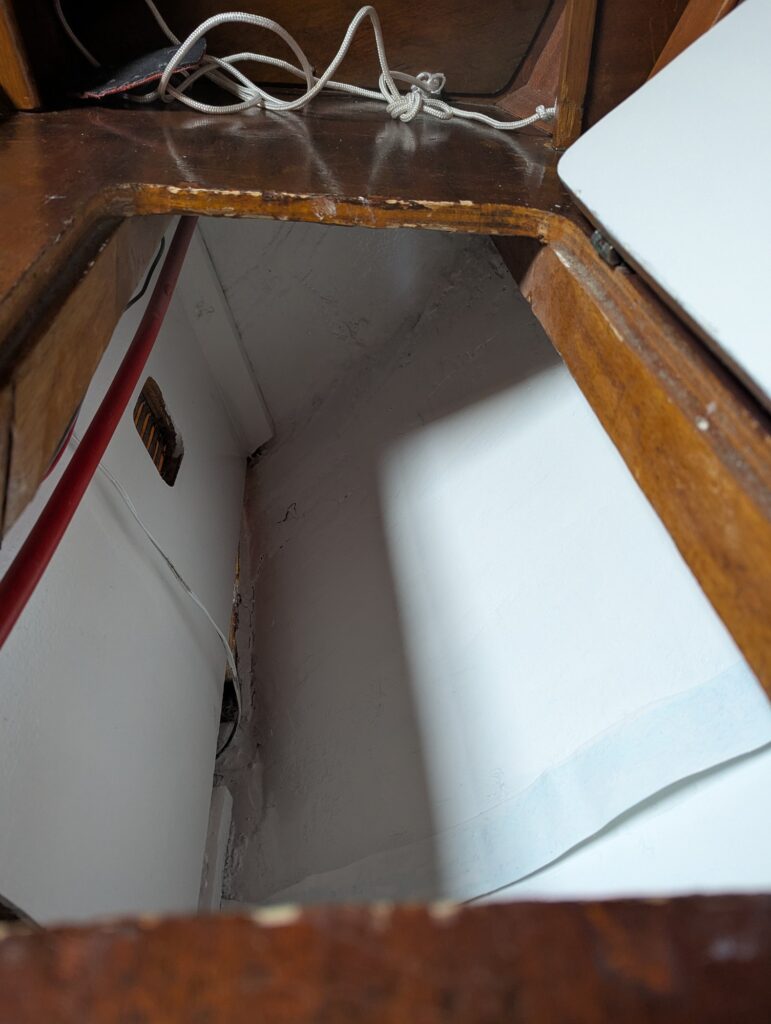

Before

We knew at the time we bought Isola Naida that the starboard and bow sponsons of our RHIB each suffered a slow leak. This meant that we’ve had to reinflate two of the three sponsons daily. The previous owners hadn’t had the opportunity to haul her our and go on a leak-finding mission.

The Vision

Our goal is to uncover and clean the tender in order to identify any leaks and any areas with the potential to cause an issue in the future. After the leaks are identified, we will address each one by affixing a patch. Any areas of significant wear we will attempt to reinforce with patching material.

In a separate but related project we will sew a new tube cover which will be reinforced with plastic sheeting to act as a durable protective barrier for the Hypalon sponsons moving forward.

The Plan

The plan is as follows:

- Wash and scrub the RHIB with soapy water for an initial clean and to help identify leaks

- Wash and scrub the RHIB with Spray Nine to further clean and degrease the RHIB

- Sand area around identified leaks to prepare for patching

- Wash sanded area with Acetone to ensure patch adherence

- Apply two part adhesive to sponson and patch material

- Test sponsons to ensure all leaks have been addressed.

Step 1: Soap Wash

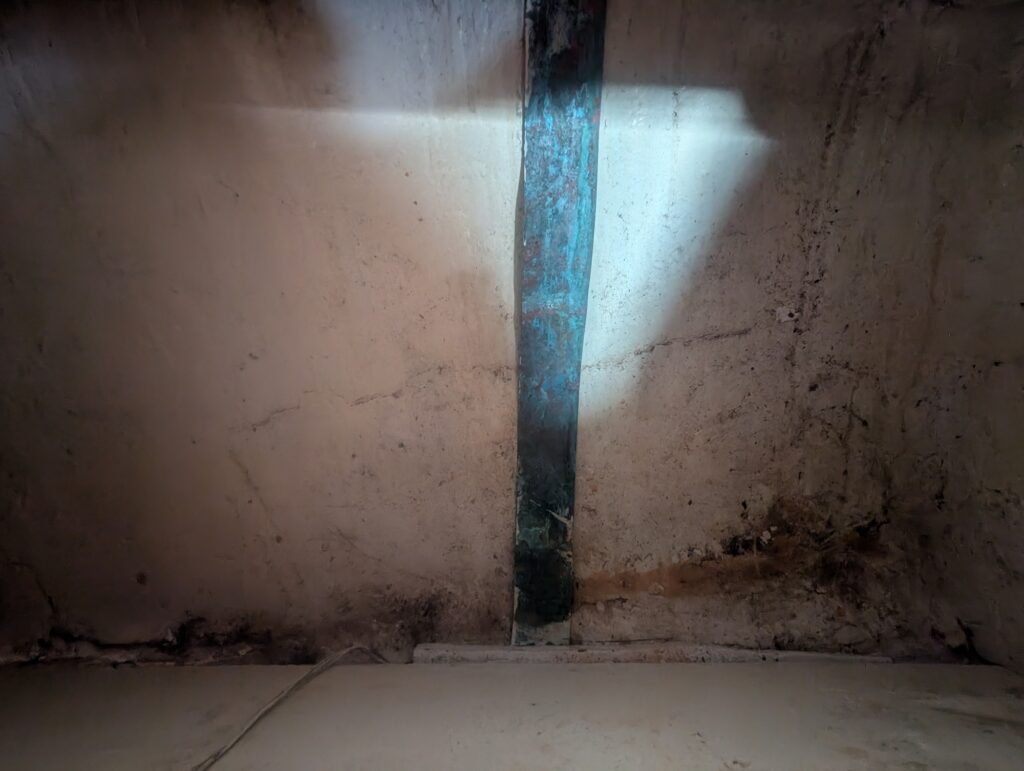

On 27 September, D’Arcy took advantage of the tender being our of the water to begin cleaning the boat and finding leaks. Using a spray bottle with a 1:4 mixture of Dawn dish soap to water, he began spraying sections of the sponsons and used a stiff bristle brush to help remove dirt and lather the soap. Lathering the soap helps to create an even distribution of bubbles which further helps the larger bubbles formed by air leaks to stand out.

We quickly discovered five leaks – four were pinhole leaks and one was a very fine slice. All of the leaks were located on the starboard bow of the boat. This bit of information immediately exposed the culprit: Isola Naida’s boarding ladder!

Isola Naida’s ladder swings over the port side toe-rail and hinges at the midpoint. When the lower half of the ladder is in the upright position instead of lowered into the water, the ends of the stainless steel tubing that makes up the ladder is exposed. This happens to be the perfect height for making contact with the RHIB’s sponsons. This was a known issue which we had discussed with Isola Nadia’s previous owners.

Step 2: Degreasing

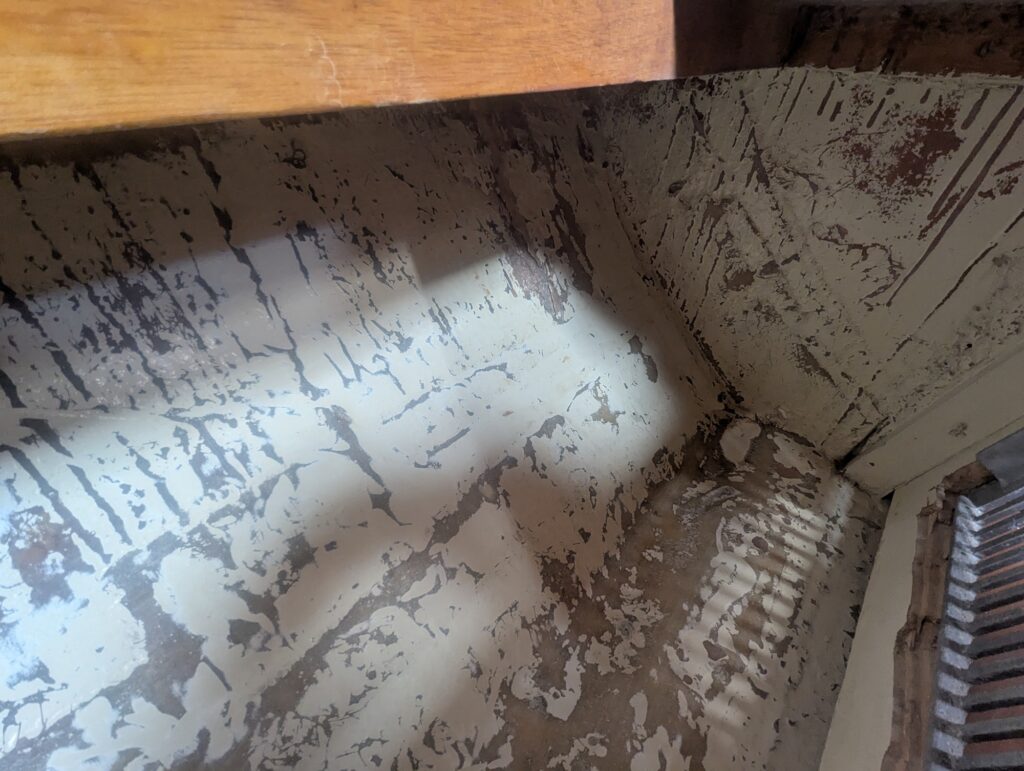

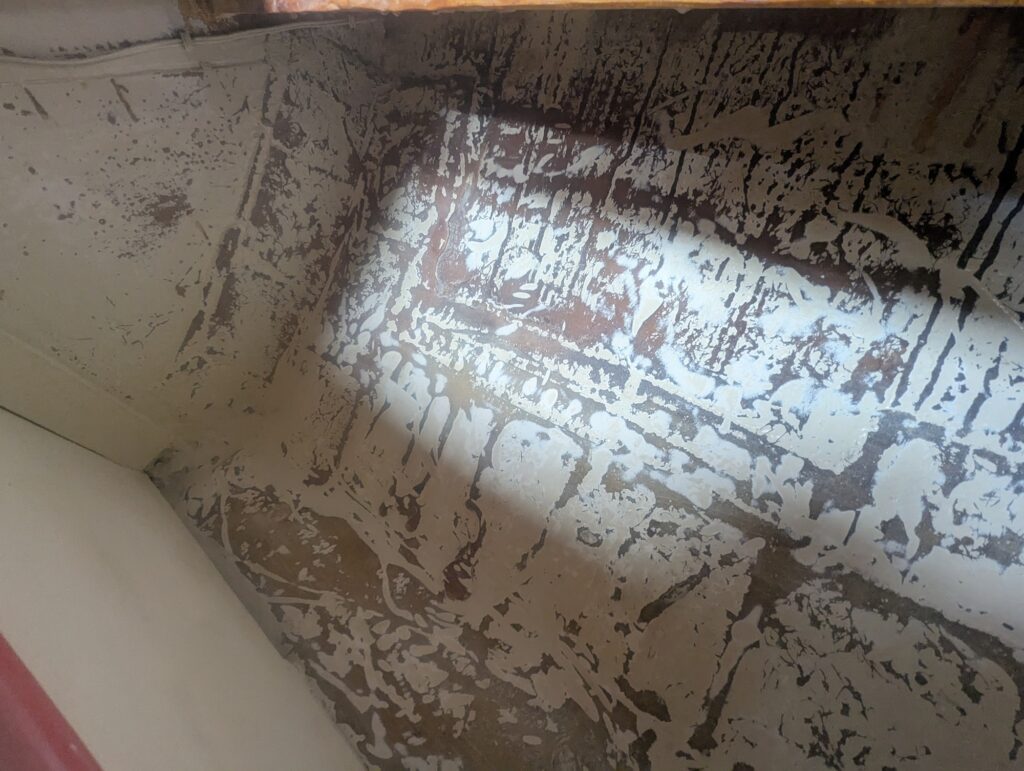

On 5 October, D’Arcy returned to degrease the tender and perform a deeper cleaning. This also ensured that we hadn’t missed any leaks in our original search. We used Marine Spray Nine Heavy Duty cleaner to degrease the Hypalon sponsons and the interior hull.

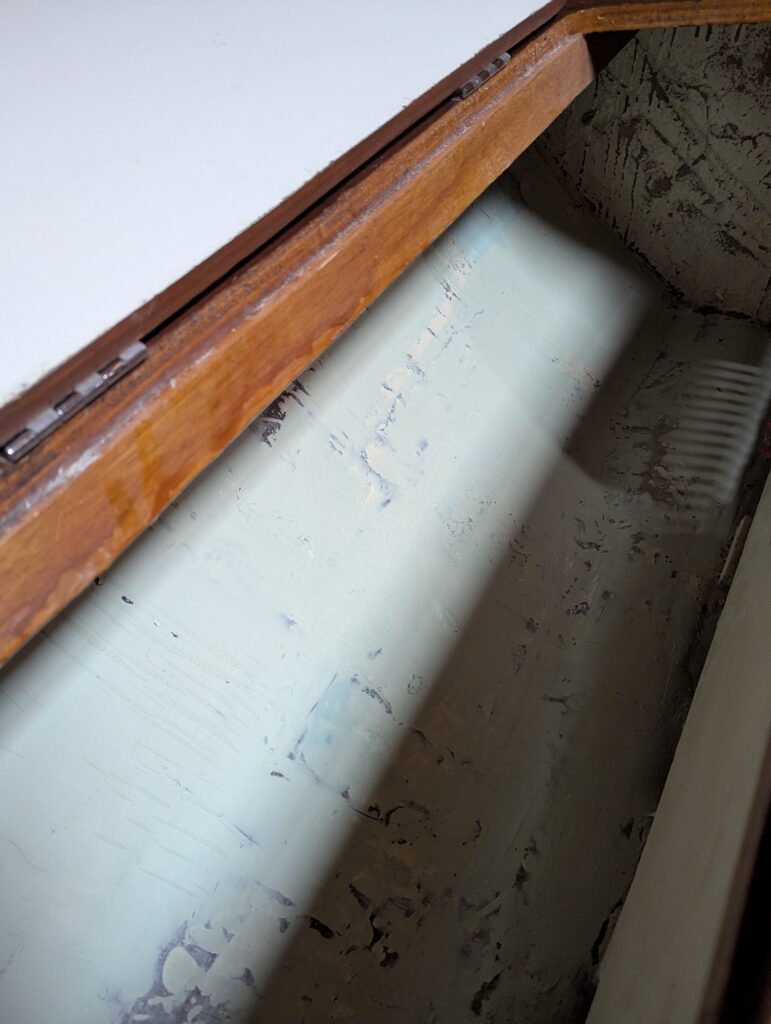

In the process, we removed the old North Carolina registration plates that had been affixed to the port and starboard side sponsons. This exposed some more spots where the neoprene outer layer of material had been separated from the Hypalon backing. We’ll reinforce these areas when we patch the leaks to help protect the sponsons as much as possible.

We won’t be able to reinforce the handles at this point. Structurally they are fine, repairs to the handles are purely cosmetic. We’ve made a note to address the handles in the future.

This post will be updated with the remaining steps as the work is completed. Come back soon to see the progress and results!